A turning point – Starting off the three decade shift in manufacturing.

The year is 1986 – Motorola develops the Six Sigma process to improve quality and reduce costs. Whether a manufacturer’s goal is to reduce pollution or increase customer satisfaction, the Six Sigma process seeks to improve quality in manufacturing. It does this by identifying and removing causes of defects and variability through a defined methodology. Quality improvement processes like Six Sigma spanned the concepts that lead to higher quality processes among all levels of a manufacturing business. Gone was the idea that quality management could only be regulated to places like the production floor.

It was also at this time that General Motors began assembling front-wheel-drive axles at its Vanguard plant in Saginaw, MI. Considered the “factory of the future”, this plant spawned controversy around features in advanced automation, such as robots and automated guided vehicles. The Vanguard plant was a test facility where they would exclude third shift due to these technological advances. GM’s goal at the time was to create a “lights out” facility. This goal however was never reached but techniques at this facility would reverberate throughout other GM plants and manufacturing as a whole for years to come.

Rising to the challenge – An industry in need.

It’s safe to say that during this time manufacturing was on the forefront of new technology through “factory of the future” applications. The industry pushed the boundaries of quality improvements to processes and established new guidelines for all levels of a company. A product of the same year, these concepts made up the core foundation of NUTEC when it was officially established in 1986. Design teams were needed more than ever to make future applications of manufacturing facilities a reality. A design team also needed the ability to thoroughly exemplify the now rising quality improvement techniques for all levels of the manufacturing organization’s project team.

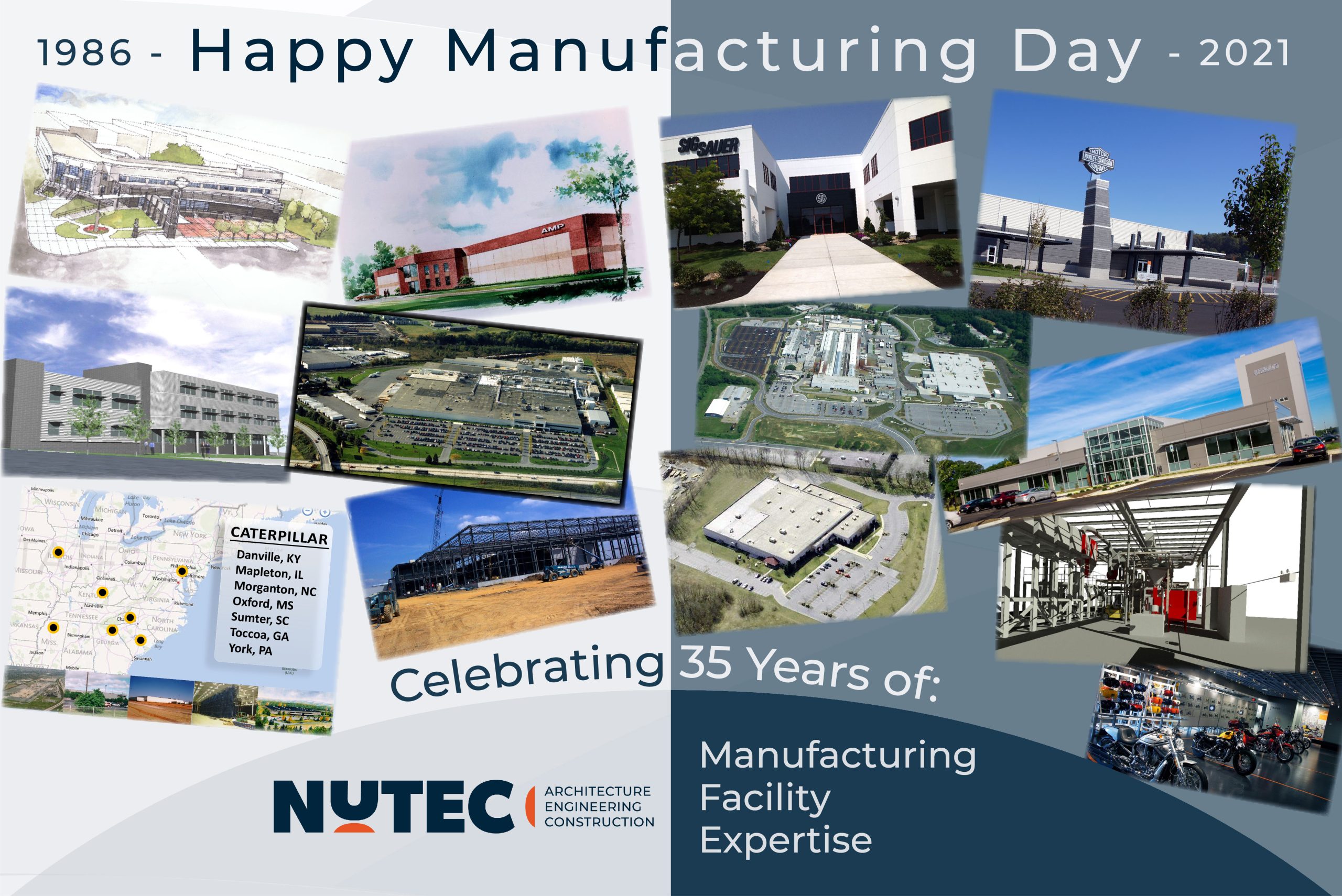

However, NUTEC’s principals for designing with new technology and quality management in mind didn’t come out of the ether. Upon their creation was the dissolution and restructuration of Noonan Engineering, a company known for their work in the manufacturing and industrial space at a critical industrial hub in the US, York County. Caterpillar Inc., originally a client of Noonan Engineering dating back to the 1960s, became a strong leg for NUTEC. Continuing to foster the relationship, projects for Caterpillar quickly expanded to multiple locations and project types throughout the US. This allowed NUTEC to continually improve their core foundation of projects in the manufacturing sector. This consistent improvement of each unique facility while employing the principals of new technology and quality management lead to a trend of long-standing relationships with some of the top manufacturer’s in the US. More industrial clients at the time of NUTEC’s beginnings included: RR Donnelley, a continued relationship through all rebrands of AMP to Tyco Electronics to TE Connectivity, Harley-Davidson Motor Co., Armstrong World Industries, BAE Systems, NVR Building Products, and Pfaltzgraff.

Continuing the charge – Success for the future.

Over the years NUTEC continues to support manufacturers and projects of all sizes. To best accommodate evolving trends and increasing percentage of unique manufacturing processes NUTEC expanded their services to include: construction, facility management, and facility planning services for clients seeking a full-service design-build partner. With the ability to perform as either a “one-stop-shop” or partner services for projects both small and large, NUTEC continues to evolve with their manufacturing clients. They have since provided, and in some cases continued, a range of these services to clients such as: Harley-Davidson Motor Co., SIG Sauer, Tempur Sealy International, Inc., Northrop Grumman, BAE Systems, Uzin Utz North America, Inc., and Dentsply International to name a few. NUTEC’s story continues to focus on helping their clients’ unique processes succeed for the ever-expanding diversity of manufacturing facilities. A 35-year history with manufacturers allows them to provide expertise to the segment in which NUTEC and our nation thrives. NUTEC foresees their continued involvement in the manufacturing and industrial space for years to come. Quality process improvements and technological advances will always be at the heart of what makes both NUTEC and Manufacturing succeed.

On top of these principals NUTEC is now emphasizing a commitment to collaboration to understand the ever-changing needs of their manufacturers:

“We specialize in delivering uncommon solutions to bring our clients’ visions to life. We develop these uncommon solutions by exploring new horizons together. And that exploration is more relevant than ever given the current national landscape. We see that manufacturers are putting untold effort into making production work, and we’re challenging ourselves to do the same and come together as a team. After all, our best work is a reflection of our clients and partners.” – NUTEC

To learn more about NUTEC’s history, check out NUTEC Then and Now